AOI, E-Test & Final Inspection

Quality is the top priority at Unimicron Germany. In order to manufacture PCBs in accordance with the highest quality standards, a lot of inspection stations are installed during the manufacturing process:

We carry out an AOI - automatic optical inspection - both for the inner and outer layers. Here, the PCBs are compared with the customer data any checked for any errors.

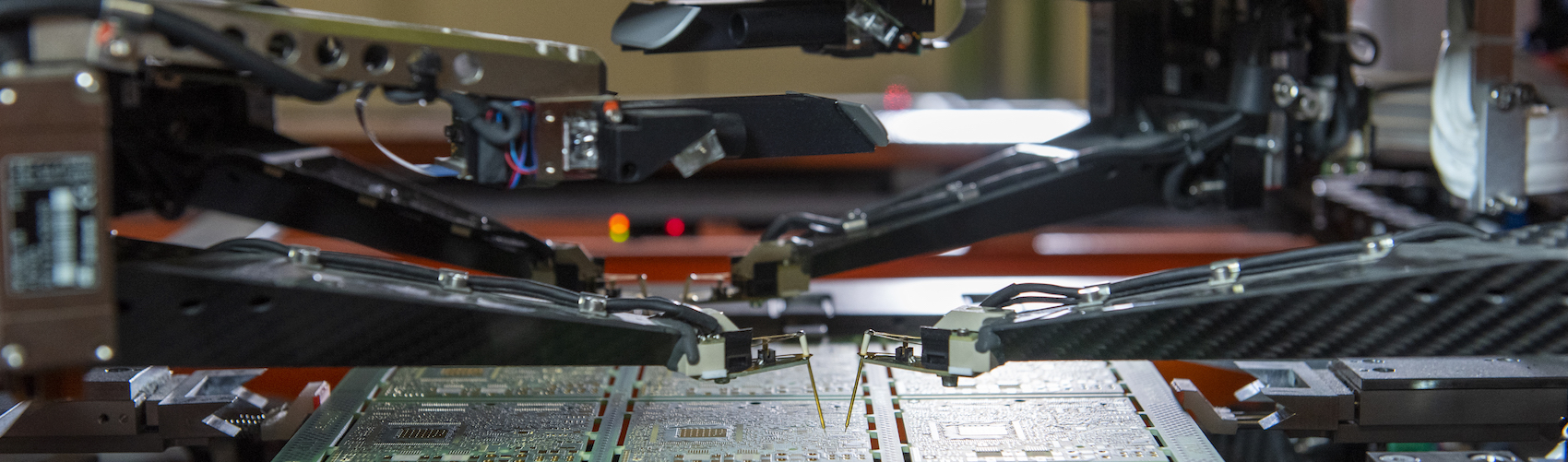

The electrical function is tested during the E-test. Depending on the complexity and lot size, we either use the flying probe or testing with an adapter.

Final quality and quantity checking takes place during final inspection. This is done using visual inspection manually and in special cases with the microscope or via automatic AVI - automatic visual inspection.

An excellently equipped physics laboratory completes our quality profile. Hardly any manufacturer has this wide-ranging equipment. Various tests are inhouse available in order to keep the high quality standards and also to further qualify processes: temperature cycle tests, CAF tests, tests for insulation resistance and temperature storage as well as tests with the scanning electron microscope or the reflow oven.