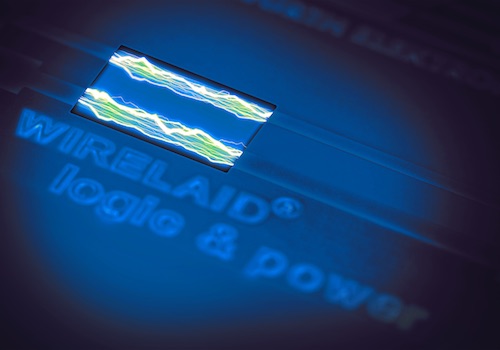

Miniaturisation and Optimised Integration

Smart Solutions for an Optimal Use Concerning Miniaturisation

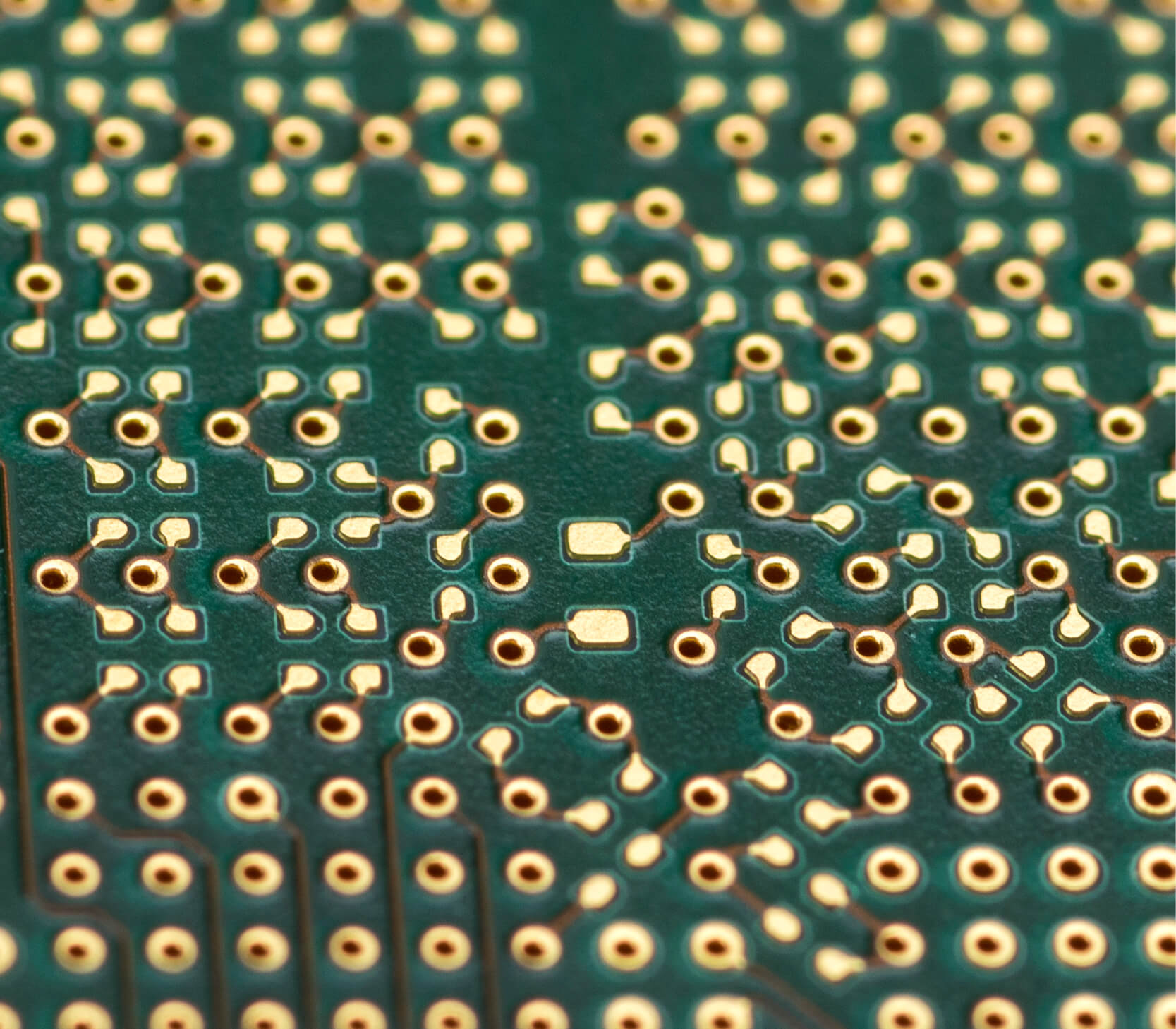

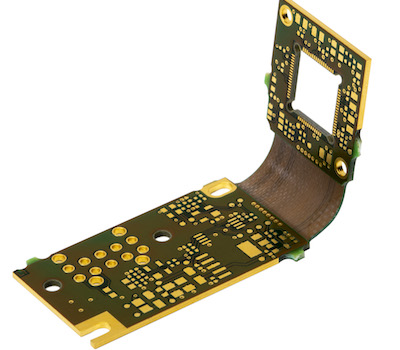

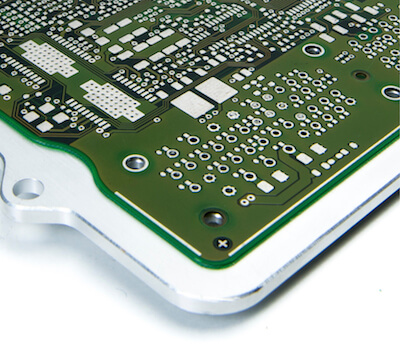

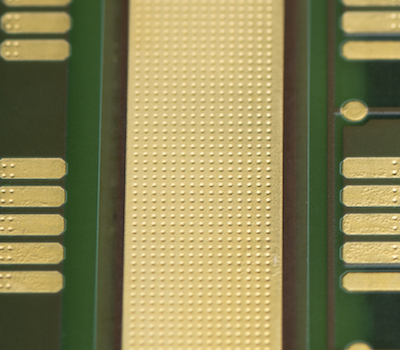

Miniaturisation is a driving factor influencing electronics. Small and light-weight equipment and assemblies are required. On the one hand the structures on the PCBs are becoming more and more finer in order to be able to cater to the smaller connection grids of high performance components too. On the other hand the assembly spaces are frequently so minimised that the printed circuit boards are “folded in” as rigid-flex variants, or power and control electronics which used to be mainly separated are combined in just one single circuit board.

Unimicron Germany offers many solution concepts for optimising integration.